This thread is for anyone working on personal projects to share their progress, and hold themselves somewhat accountable to a group of peers.

Post your project, your progress from last week, and what you hope to accomplish this week.

If you want to be pinged with a reminder asking about your project, let me know, and I'll harass you each week until you cancel the service.

Well, it seems this thread is still not doing too badly relative to the other regular threads, so let's stay on a weekly pace.

Jump in the discussion.

No email address required.

Notes -

My cooling vest project is moving again, at long last!

I live in Florida, in August, and my work schedule relative to my work site's means that I'm walking across a half-mile of parking lot in full morning sun. NightHawkInLight, a popular science youtuber, recently ran across (https://youtube.com/watch?v=Nqxjfp4Gi0k) a Phase Change Material that's amenable to DIY-level resources, so I've taken it upon myself to package it in a wearable form. Academic writeup at https://www.researchgate.net/publication/316893824_Preparation_and_thermal_properties_of_Glauber's_salt-based_phase-change_materials_for_Qinghai-Tibet_Plateau_solar_greenhouses .

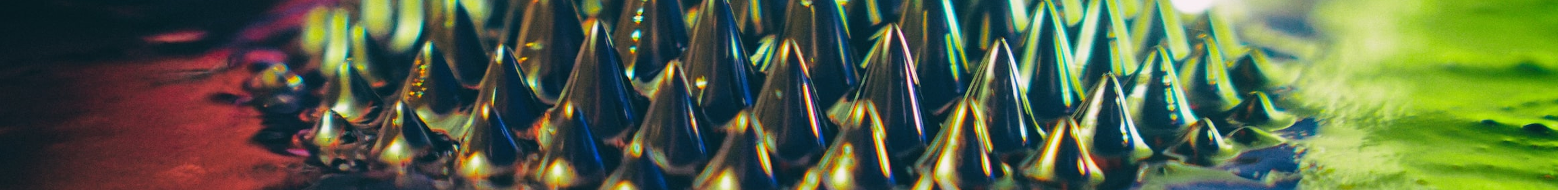

Phase Change Material: a material that melts and freezes at a tuneable temperature. This is the stuff that keeps your pillow foam cold at night. This is not chemical cold packs, it's only melting and freezing - the entire connected volume of the material will fight a temperature change to the other side of the phase change point as long as any part of it hasn't absorbed enough joules to implement the phase change. If the temperature you care about is 32F, you can use water just fine. If you want a little less than that, add rock salt, like the North does every winter to clear roads and driveways. If your temperature is about 95F, you can make a saturated water solution of sodium sulfate, aka Glauber's salt. Then, if you want it to be relevant to human-compatible temperatures, dope it with sodium chloride, and you get the melting temp to about 65F. Then, if you put it into flexible pouches held more or less against the skin, it rescues engineers from showing up dripping to their cube farm.

I've been treating the PCM as more or less turnkey and solved, so the only obstacle is making pouches to a) hold a useful amount of PCM, b) against a curved surface (me), c) in a structure that doesn't impair other forms of cooling. I've chosen heavy PVC sheet for this, and had some trouble getting it to fuse to itself - I'd made a temperature-controlled heat spreader out of a brass bar and a cartridge heater, controlled by an off-the-shelf PID controller and solid-state relay, but it didn't heat the far sheet effectively enough to fuse at the heated zone. A colleague pointed out that pipe cement is really PVC cement, so I figured out over the weekend how to mask that zone to pretty tightly control where the joint between sheets occurs - masking tape works fine - and last night how to heat and form the PVC sheet using a vacuformer. So now I just need to make the forms for the pouches, make the front sheet with the vacuformer, and glue on the backing sheet.

Hey, I made some of these a few years ago. I tried to arrange manufacturing to sell them to hot areas. PM me and we can chat!

N.b. they make vests with pockets to insert ice packs. But even better, put material on large veins to cool the bloodstream. The PCMs do crazy stuff to ferrous metals btw.

PM'd

More options

Context Copy link

More options

Context Copy link

Registering that I've been considering going down the route of trying to do something like this for a while, and I would love to have any updates that could be encouraging me to finally move it toward the top of my list.

More options

Context Copy link

Hm. If the PVC sheets give you too many issues, I'd heard of prototypes for fursuit cooling vests use vacuum sealing or sous vide bags. They're not going to be as puncture-resistant as PVC, but if it ends up being too heavy or too annoying to form, may be worth trying.

More options

Context Copy link

More options

Context Copy link